Isikhwama sokukhiya: Ithuluzi Elibalulekile Lokuphepha Kwasemsebenzini

Kunoma iyiphi indawo yokusebenza, ukuphepha kubaluleke kakhulu. Lokhu kuyiqiniso ikakhulukazi ezindaweni zezimboni lapho abasebenzi bechayeka ezingozini ezihlukahlukene nsuku zonke. Isici esisodwa esibalulekile sokuphepha kulezi zindawo zokusebenza ukuqaliswa okufanele kwezinqubo zokukhiya/zokuphuma. Lezi zinqubo zenzelwe ukuqinisekisa ukuthi okokusebenza zivalwa kahle futhi ngeke ziphinde zivulwe kuze kuqedwe ukunakekela noma ukulungisa. Ukuze usebenzise ngempumelelo izinqubo zokukhiya/zokuphuma, ukuba namathuluzi afanele kubalulekile. Elinye ithuluzi elinjalo yisikhwama sokukhiya.

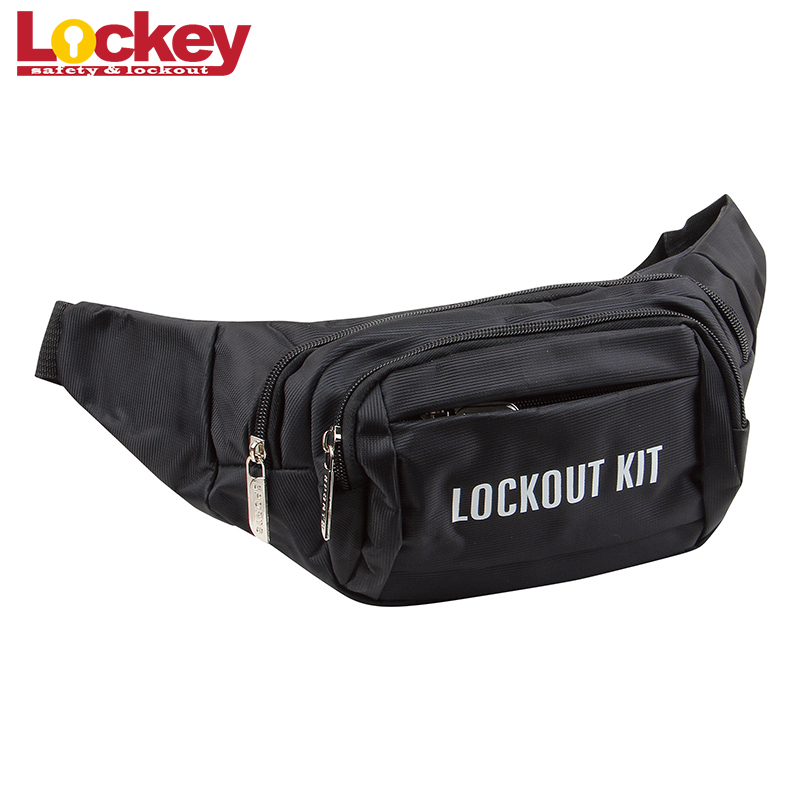

Aisikhwama sokukhiyaiyikhithi ekhethekile equkethe zonke izinto ezidingekayo zokukhiya ngaphandle noma ukumaka impahla ngesikhathi sokulungiswa noma ukulungiswa. Lezi zikhwama ngokuvamile zenziwe ngezinto ezihlala isikhathi eside njengenayiloni noma i-polyester futhi zenzelwe ukumelana nobunzima bezindawo zezimboni. Ziyithuluzi elibalulekile lanoma iyiphi indawo yokusebenza edinga ukuqinisekisa ukuphepha kwabasebenzi bayo ngesikhathi sokulungisa nokulungisa imisebenzi.

Okuqukethwe kwesikhwama sokukhiya kungahluka, kodwa kunezinto ezithile ezibalulekile ezivame ukufakwa. Lokhu kungase kuhlanganise amadivayisi wokukhiya ngaphandle njengama-padlock, ama-haps, namathayi ekhebula, kanye nomaka namalebula okuhlonza okokusebenza okukhiyelwa ngaphandle. Ezinye izinto ezingase zifakwe esikhwameni sokukhiya okhiye bokukhiya, izinto zikagesi zokuvala izinto, namadivayisi wokuvala ama-valve. Lawa mathuluzi abalulekile ekuqinisekiseni ukuthi okokusebenza kuvalwe kahle futhi akukwazi ukuvulwa ngephutha ngabasebenzi abangagunyaziwe.

Enye yezinto ezibaluleke kakhulu ku-aisikhwama sokukhiyaingidi. Lezi zikhiye zenzelwe ukuthi zilingane ezinhlotsheni ezahlukene zemithombo yamandla njengogesi, i-pneumatic, i-hydraulic, ne-mechanical. Ngokuvamile zenziwa ngezinto ezihlala isikhathi eside njengensimbi engagqwali noma i-aluminium futhi zenzelwe ukumelana nezindawo zezimboni ezinokhahlo. Ukusetshenziswa kwama-padlocks kuyingxenye ebalulekile yeukukhiya/ukuphumaizinqubo njengoba zivimbela ukuqaliswa kwemishini ngengozi ngabasebenzi abangagunyaziwe.

Ama-Hasps angenye ingxenye ebalulekile yesikhwama sokukhiya. Lawa madivaysi asetshenziselwa ukuvikela i-padlock endaweni, ukuqinisekisa ukuthi okokusebenza akukwazi ukusebenza kuze kuqedwe umsebenzi wokulungisa noma wokukhanda. Ama-hasps ngokuvamile enziwa ngezinto eziqinile njengensimbi noma i-aluminium futhi aklanyelwe ukumelana nobunzima bokusetshenziswa kwezimboni. Bayingxenye ebalulekile yeukukhiya/ukuphumainqubo njengoba zinikeza isendlalelo esengeziwe sokuvikela ukuvimbela ukufinyelela okungagunyaziwe kumishini.

Othayi bekhebula nabo bayingxenye ebalulekile yesikhwama sokukhiya. Lezi zibopho zisetshenziselwa ukuvikela amadivayisi wokuvala ngaphandle endaweni, ukuqinisekisa ukuthi awakwazi ukususwa kuze kuqedwe umsebenzi wokulungisa noma wokulungisa. Othayi bekhebula ngokuvamile benziwa ngezinto eziqinile njengenayiloni futhi baklanyelwe ukumelana nezimo ezinzima zezindawo zezimboni. Ziyithuluzi elibalulekile lokuqinisekisa ukuthi okokusebenza kuhlala kukhiyelwe ngaphandle ngesikhathi sokulungisa nokulungisa.

Ngokungeziwe kumadivayisi wokukhiya, isikhwama sokukhiya singase futhi sibe namathegi namalebula okuhlonza okokusebenza okukhiyelwa ngaphandle. Lawa mathegi ngokuvamile enziwa ngezinto ezihlala isikhathi eside njengepulasitiki noma i-vinyl futhi aklanyelwe ukumelana nobunzima bezindawo zezimboni. Ziyingxenye ebalulekile yenqubo yokukhiya ngaphandle/ye-tagout njengoba zinikeza inkomba ecacile yokuthi okokusebenza kuphelelwe yisevisi okwesikhashana futhi akufanele kusetshenziswe.

Okhiye bokukhiya bangenye into ebalulekile engase ifakwe esikhwameni sokukhiya. Lezi zikhiye zisetshenziselwa ukuvula ama-padlock nama-haps uma umsebenzi wokulungisa noma wokulungisa usuqediwe. Ngokuvamile zigcinwa endaweni evikelekile futhi zifinyeleleka kuphela kubasebenzi abagunyaziwe. Okhiye be-Lockout bayingxenye ebalulekile ye-ukukhiya/ukuphumanjengoba beqinisekisa ukuthi okokusebenza kungasetshenziswa ngokuphepha uma umsebenzi wokulungisa noma wokuwulungisa usuqediwe.

Imishini yokuvala ugesi ingenye ingxenye ebalulekile yesikhwama sokukhiya. Lawa madivaysi aklanyelwe ukuvimbela ukuqaliswa kwemishini kagesi ngengozi ngesikhathi sokulungiswa noma ukulungisa. Ngokuvamile zenziwe ngezinto ezihlala isikhathi eside njengepulasitiki noma inayiloni futhi zenzelwe ukumelana nobunzima bokusetshenziswa kwezimboni. Imishini yokukhiya ugesi iyingxenye ebalulekile yeukukhiya/ukuphumainqubo njengoba zihlinzeka ngesendlalelo esengeziwe sokuphepha sokuvimbela izigameko ezibandakanya imishini kagesi.

Amadivayisi wokuvala ama-valvenazo ziyingxenye ebalulekile yesikhwama sokukhiya. Lawa madivaysi asetshenziselwa ukuvala ukuphuma koketshezi emapayipini noma kolayini ngesikhathi sokulungiswa noma ukulungisa. Ngokuvamile zenziwa ngezinto ezihlala isikhathi eside njengensimbi noma i-aluminium futhi zenzelwe ukumelana nezimo ezinzima zezindawo zezimboni. Imishini yokukhiya i-valve iyingxenye ebalulekile yohleloukukhiya/ukuphumainqubo njengoba zivimbela ukukhishwa ngengozi kwezinto eziyingozi phakathi nemisebenzi yokunakekela nokulungisa.

Sengiphetha, aisikhwama sokukhiyaiyithuluzi elibalulekile lanoma iyiphi indawo yokusebenza elidinga ukuqinisekisa ukuphepha kwabasebenzi bayo ngesikhathi sokulungisa nokulungisa izinto. Lezi zikhwama ziqukethe zonke izinto ezidingekayo zokukhiya ngaphandle noma ukumaka impahla, ukuqinisekisa ukuthi ngeke zikwazi ukusebenza kuze kuqedwe umsebenzi wokulungisa noma wokukhanda. Okuqukethwe kwesikhwama sokukhiya kungase kuhluke, kodwa ngokuvamile kuhlanganisaamadivayisi wokukhiyanjengama-padlock, ama-haps, namathayi ekhebula, kanye namathegi namalebula okuhlonza okokusebenza okukhiyelwa ngaphandle. Ezinye izinto ezingase zifakwe izikhiye zokukhiya, izisetshenziswa zikagesi zokuvala, namadivayisi wokuvala ama-valve. Ngokusetshenziswa okufanele kwezinqubo zokukhiya ngaphandle/zokuthinta kanye nokusetshenziswa kwesikhwama sokukhiya, izindawo zokusebenza zingaqinisekisa ukuthi abasebenzi bazo baphephile ezingozini zokuqalisa ngephutha noma ukukhishwa kwezinto eziyingozi.

Isikhathi sokuthumela: Jan-27-2024